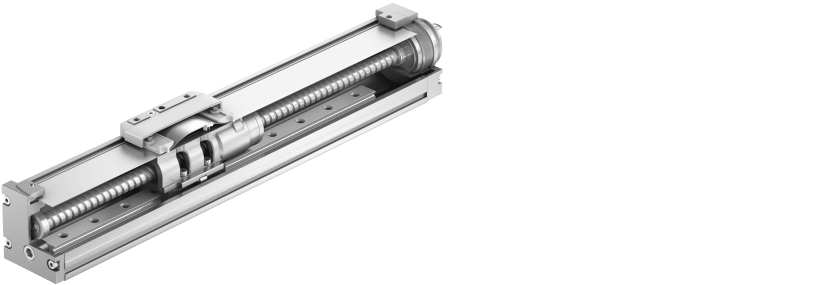

The spindle axes ELGC-BS stand out thanks to their internal spindle and recirculating ball bearing guide which are protected by a permanent stainless-steel cover strip, as well as their weight-optimised design. They promise precise and smooth running, whether installed horizontally or vertically.

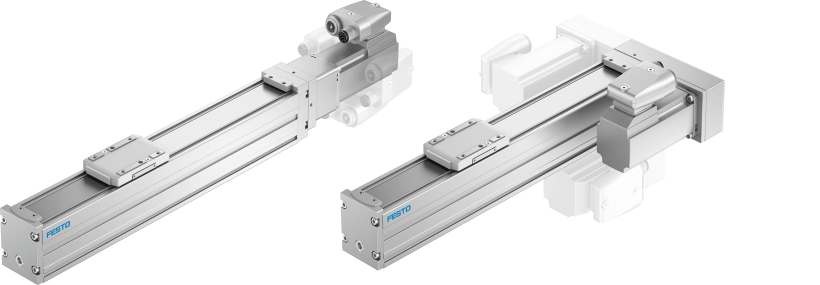

The mounting elements for axis/axis assembly enable the spindle axes ELGC-BS to be directly assembled with the toothed belt axes ELGC-TB and the mini slide EGSC without additional adapter plates.

1. Cover strip

Permanent stainless-steel cover strip protects the guide and spindle or toothed belt

2. Motor mounting

Free choice of motor positions, outlet orientations and various axial and parallel kits, can also be changed at a later date

3. "One-size-down" mounting system

Combine the basic axis with the next-size-down assembly axis without additional adapters

4. Integrated coupling

Highly compact coupling integrated into the spindle axis. Includes simple replacement for servicing, compatible with axial and parallel kit

5. Compact double bearing

High-performance, double ball bearing integrated in the axis to absorb drive forces and torque, with space-saving installation in the axis

6. Guide

Integrated recirculating ball bearing guide with a long service life and rigid precision guide rail to absorb high guide forces

7. Position sensing

Cost-effective position sensing using proximity switch SMT-8M